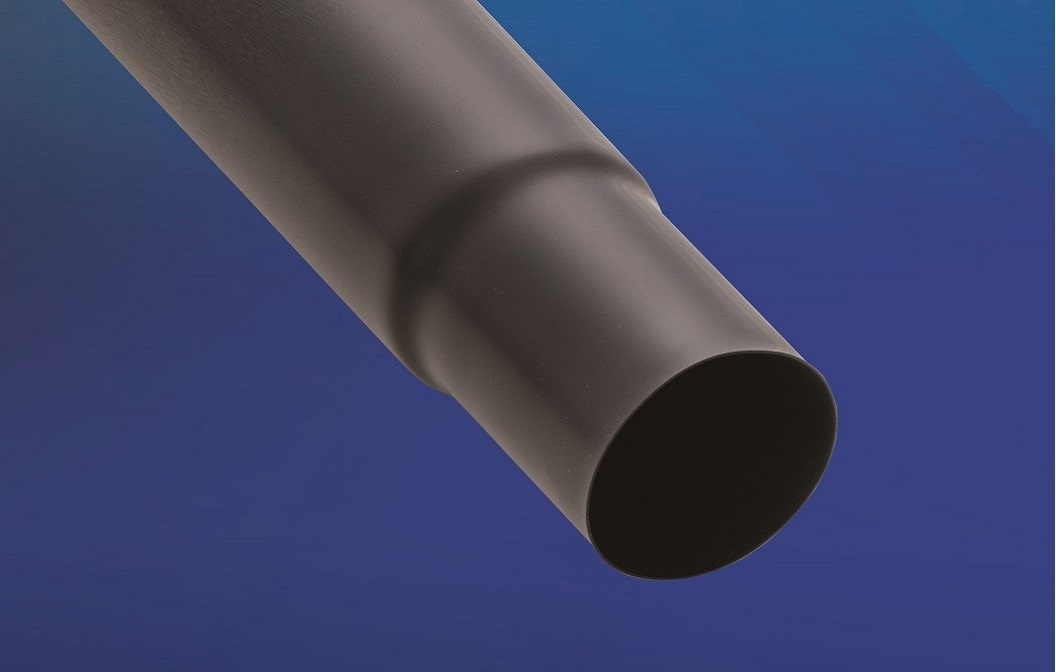

Anti-static GRC fluorine-contained resin heat-shrinkable tube.

Features

In addition to the non-adhesive characteristics of PFA fluoro resin, GRC-PB is anti-static.

- Anti-static characteristics

- Non-adhesive surface resists contamination

- Chemical resistance

Applications

- Photocopiers and printers

- Paper manufacturing and paper product manufacturing (paper and adhesive tape manufacturing machines)

- Film and sheet processing machines (laminators, and magnetic tape manufacturing machines)

- Textile and dyeing equipment (dyeing and resin processing equipment)

- Printing machinery (high-speed offset rotary press and printing machines for business forms)

- Industrial machinery (printed circuit board, semiconductor, and FPD related equipment)

Specifications

| Item Code | Inside dia. (mm) Before shrinkage | Inside dia. (mm) After shrinkage | Thickness (mm) | Standard length (mm) | Special length (mm) Note1 | Material |

|---|---|---|---|---|---|---|

| 30PB | 32 | 29 | 0.5 | 1200 | Conductive PFA | |

| 35PB | 36 | 33 | 0.5 | 1200 | Conductive PFA | |

| 40PB | 41 | 37 | 0.5 | 1200 | Conductive PFA | |

| 45PB | 51 | 43 | 0.5 | 1200 | Conductive PFA | |

| 50PB | 53 | 47 | 0.5 | 1200/1800 | Conductive PFA | |

| 55PB | 59 | 51 | 0.5 | 1200 | Conductive PFA | |

| 60PB | 65 | 56 | 0.5 | 1200/1800 | Conductive PFA | |

| 70PB | 74 | 62 | 0.5 | 1800 | Conductive PFA | |

| 75PB | 79 | 70 | 0.5 | 1800 | Conductive PFA | |

| 80PB | 84 | 75 | 0.5 | 1800 | Conductive PFA | |

| 85PB | 89 | 76 | 0.5 | 1800 | Conductive PFA | |

| 90PB | 94 | 83 | 0.5 | 1800 | Conductive PFA | |

| 100PB | 103 | 92 | 0.5 | 1800 | Conductive PFA | |

| 100PB | 106 | 93 | 0.5 | 3600 | Conductive PFA | |

| 105PB | 108 | 94 | 0.5 | 1800 | Conductive PFA | |

| 110PB | 113 | 100 | 0.5 | 1800 | Conductive PFA | |

| 120PB | 122 | 107 | 0.5 | 1800 | Conductive PFA | |

| 123PB | 127 | 115 | 0.5 | 3600 | Conductive PFA | |

| 125PB | 132 | 117 | 0.5 | 1800/3600 | Conductive PFA | |

| 135PB | 141 | 125 | 0.5 | 1800 | Conductive PFA | |

| 145PB | 150 | 129 | 0.5 | 1800 | Conductive PFA | |

| 150PB | 156 | 138 | 0.5 | 1800/3600 | Conductive PFA |

NOTES

- When making inquiries or placing an order, be sure to supply us with the accurate roller diameter and length so that we can select the optimum tube for your application.

- Contact for regarding requirements that exceed the specifications in the above table.

- This product has been specially treated to suppress generation of static electricity. It is not guaranteed to totally eliminate generation of static electricity. (Surface resistance is under 10^8.)

- Please store the tubing in a cool and dark location (30℃ or below). At higher temperatures, there is a possibility that the tube will shrink.

- The inside diameter after shrinkage is the measurement made after heating to 200℃ for 10 minutes. It is not a guaranteed value.

- Cut length is 400 mm or above, with a pitch of 100 mm. Any quantity of tube order is welcome.

- If GRC is used in places where the temperature exceeds 100℃ or where the nip pressure is too high, there is a strong possibility that the GRC may slip or cause wrinkle. Consult Gunze regarding such cases.

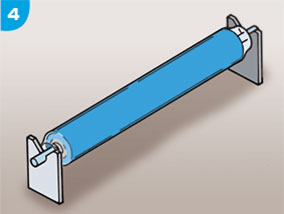

How to Apply GF Tube

Construction Method

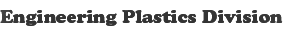

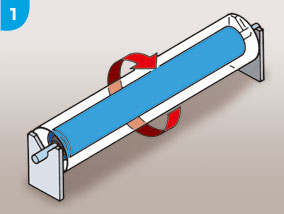

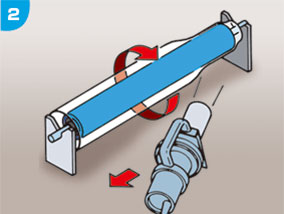

Illustration

- Please use the heat gun on the market.

- Please choose inside dia, which is nearly roller’s diameter. The length of GRC that is around 200mm longer than the length of roller is preferable.

POINT

- Spin the roll at constant speed.

- Shrink GRC from one side. The standard temperature of heat air is 150~200℃ at the surface of GRC.

- Heat rollgun’s direction is opposite direction to movement’s direction to prevent air bubble.

- Please contact for construction technique of tube with large size dia. we prepare for the detail guidances about tube.

- Please contact for installation.

VIDEO

FAQ

-

- Is it possible to borrow construction tools?

- Yes, you can rent from us. (※Only in Japan)

-

- We do not have confidence in the construction. Is it possible to ask Gunze to give us a construction?

- Yes, we could carry out construction guidance free of charge only once at the first time.

-

- Is it possible to give construction to an irregular (oval, square, triangle / stepped, arched) roll?

- Since the shrinkage ratio of the tube is low, conformability to the shape will be limited. Please ask us for details.

-

- Is there a limit to the material of rollers?

- Since there is a risk of thermal deformation, we do not recommend low heat resistance materials such as polyurethane foam.

-

- How to deal with the end of the roller?

- Please do not cut off the tube by the roller’s length. Leaving the tube slightly longer than the roller and then shrink to be smaller than the roller’s diameter.

-

- Is it possible to cut the tube easily by scissors?

- It can be cut off easily by scissors or cutter. However, please be careful to cut the tube along the longitudinal direction in order not to leave cut marks.

-

- Is it possible to wipe the tube with solvent?

- Yes, it is possible.

-

- Is it possible to use an adhesive or tape to connect the tube?

- No, it is impossible.

-

- Is it possible to repair the entrainment of air bubbles?

- It is not possible to repair completely. Please contact us for simple repair method.

-

- How about the endurance of tubes?

- It might be different depending on customer’s usage.

-

- Is it possible to bond tubes and rolls by adhesive processing?

- It is impossible in our company. We will introduce a professional.