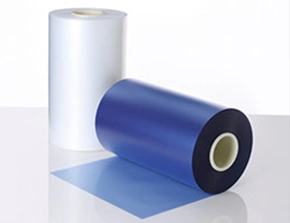

Resin Processing TechnologiesGunze’s resin processing technologies, including melt extrusion, film formation by a casting method, and melt spinning, have developed as the underlying technological base that supports our functional solutions business. We will continue to advance these core technologies so that they can help nurture new products and businesses.

Fiber Processing TechnologiesGunze’s R&D in the area of fiber processing originates from its research on cocoon filaments, so its development is intricately entwined with the history of Gunze itself. After many years of study, Gunze’s advanced knitting and weaving technologies, fiber processing technologies, and comfort evaluation technology have developed into Gunze’s core strengths. These technologies are employed not only for apparel but for industrial materials and medical applications as well.

Surface Processing TechnologiesTo meet the diversified needs of society, Gunze has sought ways to add more advanced functions to the processing of resins or fibers. As a result, Gunze has developed many new technologies, including precision printing and dispersive mixing technologies. This will contribute to the development and societal adoption of IoT (Internet of Things).

Manufacturing Technology x Equipment DevelopmentBy consistently refining the mechatronics and sensing technologies that we have developed through long years of research, Gunze develops production equipment that enables automated processes and high product quality. The development of our own manufacturing equipment supports the advancement of our core technologies. Our efforts to develop not only new products but new manufacturing processes for current products also help advance Gunze's manufacturing technologies.