Technology Strategy

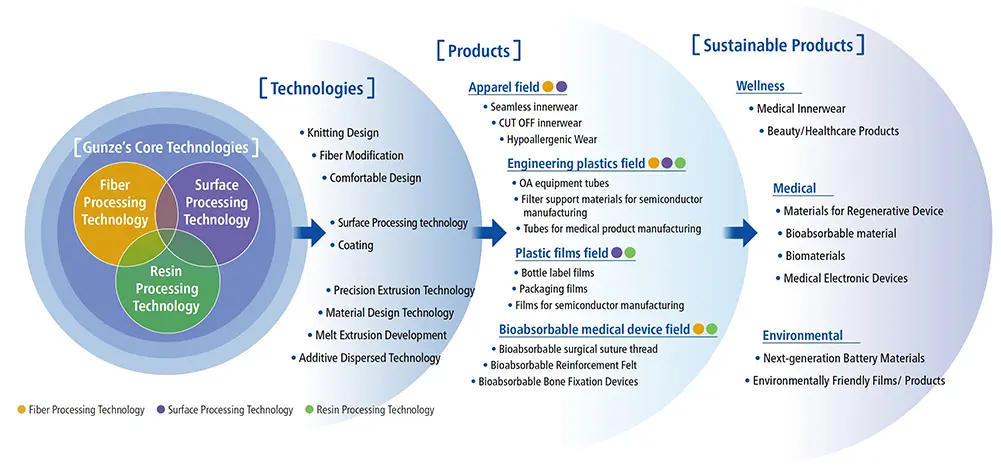

Take on the Challenge of New Value Creation by Evolving and Integrating Core TechnologiesSince our founding, we have provided a variety of products to our customers through R&D centered on various processing technologies. In apparel products, we have provided items suitable to the times by combining cotton and other fibers with processing technology and production technology that enables stable quality output. In Plastic processing, we have contributed to the provision of food packaging that is safe and reliable through multilayering and composites to achieve the functions demanded by customers. In medical materials, we have provided useful and indispensable products that include developing bioabsorbable products that reduce the burden on patients. In the business world, we provide products that are key components in the major shift from monochrome to color document printing, as well as functional materials that are indispensable in the field of advanced semiconductors.These product lines have been created by refining Gunze Core technologies of fiber processing, resin processing, andsurface processing, and we will continue to advance ourR&D activities by evolving these three core technologies and in some cases combining them with other technologies. Through the Research Committee meetings held twice a year, the Gunze Group deliberates on research themes based on progress reports. At these meetings, themes that can be immediately implemented and research themes that should be developed over a medium- to long-term span are discussed from the perspectives of Creation of New Value,Evolution of Corporate Constitution, and Environmentally. Responsible Management set forth in our Medium-termManagement Plan VISION 2030 stage1.

Creating New ValueUnder VISION 2030 stage1, we engage in various R&D activities to deliver to customers new value. We are considering applications in the energy field by developing conductive films based on further advancements in the heterogeneous lamination and dispersive mixing technologies cultivated though our functional solutions, and we are developing films with special functions with the aim of introducing them mainly in the agricultural field.

In addition, we have developed wellness and health category products such as MediCure, an underwear brand that reduces skin irritation with the aim of improving customers' quality of life. Paying close attention to the opinions of medical and nursing care professionals, weare continuing to develop health garment-based therapies that can alleviate specific problems like post-surgical pain. Going forward, we will work with local governments, medical institutions, and other companies to deliver health care products that can improve the quality of life of those who need them.In addition, we will continue to engage in R&D activities that support the advancement of existing businesses.

Evolution of Our Corporate ConstitutionAs part of efforts to promote the evolution of our corporate constitution under the basic policy of VISION 2030 stage1,we will accelerate technological innovation through DX incurrent business processes in order to promote process innovation by actively using digital technology.

For production processes, we are strengthening the development of our unique production technologies usingsensing, image recognition, and other technologies. In so doing, we are transforming factories into smart plants that enable both productivity improvement and workstyles reforms at production sites while also enhancing competitiveness by implementing automation,unmanned operations, and labor-saving measures in production and inspection processes.For sales processes, we are implementing initiatives to increase sales and improve the accuracy of SCM planning based on demand forecasts and reduce losses through customer and market analysis using big data and AI.Targeted under VISION 2030 stage1, we are building a common SCM platform for the apparel business to enable the transformation to a business model centered on ECand SPA. In indirect business processes, there are currently numerous manual analog operations for which we allocate human resources. To address this, we are working to streamline operations by taking stock of targeted processes, revamping existing business processes, and utilizing automation tools such as RPA to simply them.

「Technological Strategies for Mainstay Businesses under VISION 2030 stage1

Plastic Films

In the plastic films field, Gunze mainly supplies films laminated with different materials to produce characteristics not replicated by other companies.Since laminated films need to be separated when they are recycled, we are developing separation and other technologies that control quality of recycled raw materials.

Medical

MedicalTo date, our medical business has focused on the development of medical devices that specialize in bioabsorbable materials. This is a major strength and core technology of our business. Going forward, we will continue to give top priority to development that takes advantage of this strength. In addition, we intend to expand our core technology by taking on the challenge of developing biomaterials and medical electronic devices utilizing our expertise in bioabsorbable materials.

Apparel

We will develop automation factories both in Japan and overseas using digital technology promoted as a means to strengthen our corporate constitution. In addition, we secure market superiority through high value-added technology and develop new products as a technology-oriented company. We also conduct agile process innovation by seamlessly linking sales, production, and supply through the construction of an SCM platform system.

Environmentally Responsible ManagementGunze engages in R&D activities to reduce environmental impact, which it positions as an important issue. In each of the existing production divisions, we are conducting various technical studies mainly on improving the efficiency of energy used and production technology initiatives like recycling. In cooperation with universities and other organizations, we are also exploring the feasibility of CO2 absorption and fixation by combining our film technology developed to date with biotechnology.Furthermore, we continue R&D activities in cooperation with other companies to upcycle textile products and create new added value.

Innovation through processing technologies