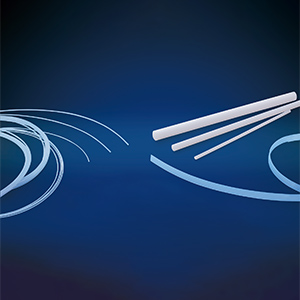

Seamless belt

Seamless Belt

GF Tube is a trademark or registered trademark of Gunze Limited.

GF Tube is a trademark or registered trademark of Gunze Limited.

Seamless belts made of engineering plastics.

Resistance is controlled by dispersion technology of conductive materials. (Surface resistance 10³ to 10¹⁴ Ω)

Thermal and mechanical properties such as thermal conductivity and stiffness can be customized upon request.

In addition, coatings and dual-layered film can be used to add cast-releasing and other functions to the surface.

The edges are reinforced with tape and processed to give an anti-snaking function.

Since this product is made-to-order, please contact our sales office.

We will provide the best solution to meet your request.

GF Tube is a trademark or registered trademark of Gunze Limited.

GF Tube is a trademark or registered trademark of Gunze Limited.

Product videos

Features

Conductive

Heat resistant

Uses

- Office equipment belts

- Fusing, transferring, developing, paper conveying, etc.

- Food processing belts

- Processing, conveyance, etc.

- Belts for general machinery

- Drive, conveyance, etc.

- Heat-resistant insulating tubes

- Heaters, thermistors, etc.

- Semiconductor applications

- Ultrapure water pipes, gaskets, etc.

- Electronic components

- FPC, TAB tape, etc.

- Telecommunication applications

- Optical fiber protection, interlayer materials, etc.

- Acoustic components

- Vibration plates, voice coil bobbins

- Leisure applications

- Molding and reinforcement of fishing rods, golf shafts, etc.

Available specifications

1.By uniformly dispersing conductive materials, resistance can be controlled as desired.

It is possible to stabilize resistance within one digit (in surface resistance 10³ to 10¹⁴ Ω).

2. Using filler dispersion, thermal and mechanical properties, such as improved thermal conductivity and rigidity, can be varied according to needs.

3. The surface can be coated with silicon or fluoropolymers resin to provide cast-releasing properties.

4. Two layers of film can be used to provide different functions on the front and back sides.

5. The edges can be reinforced with tape, or processed to give an anti-snaking function.