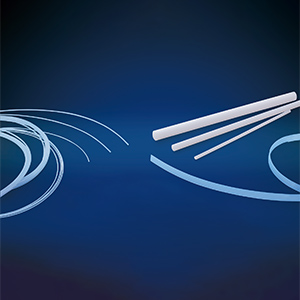

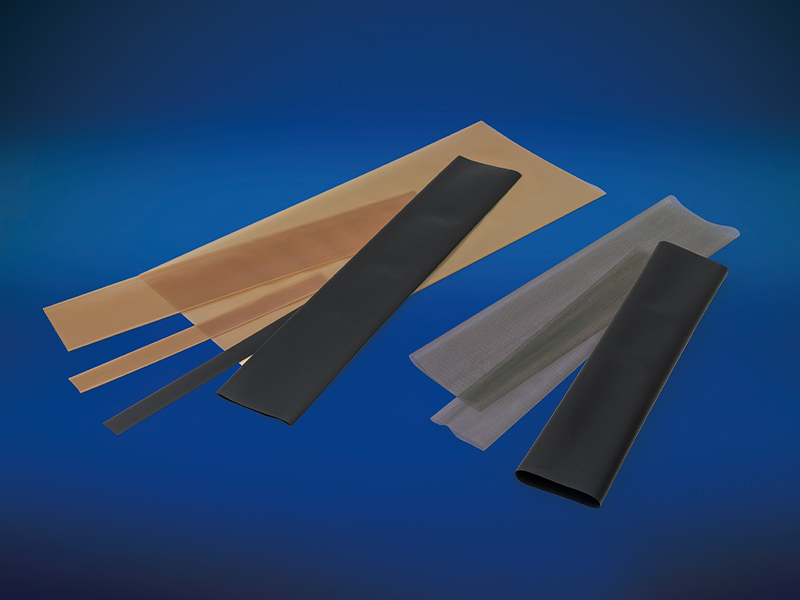

Thin-walled tube

GF TUBE®

GF Tube is a trademark or registered trademark of Gunze Limited.

GF Tube is a trademark or registered trademark of Gunze Limited.

- TST

Heat-shrinkable tubing made of fluororesin FEP.

We have successfully thinned the film and offer it in rolls (long lengths).

It is also possible to add coloring and conductivity.

GF Tube is a trademark or registered trademark of Gunze Limited.

GF Tube is a trademark or registered trademark of Gunze Limited.

Features

Water repellent, non-adhesive

Chemical resistant

Weather resistant

Slippery

Uses

Protection for manufacturing jigs

Release agent for casting materials

Fluorescent tube scattering prevention

Conveyor dirt prevention and protection

Insulating film applications for electronic components

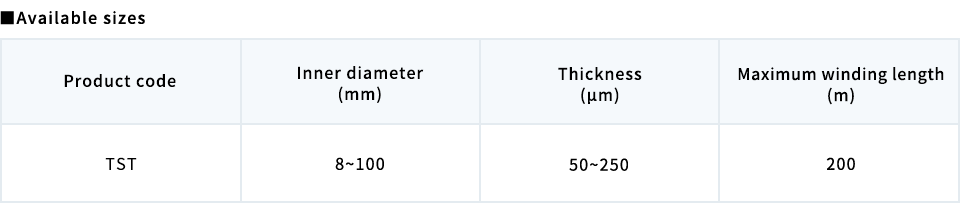

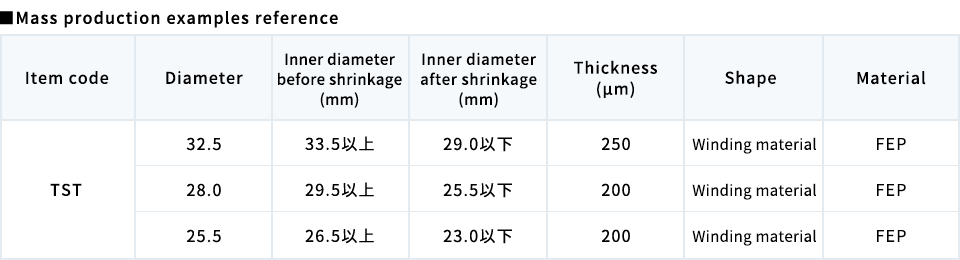

Standard specifications

Since this product is made-to-order, please contact our sales office.

We will provide the best solution to meet your request.

Scroll to see more

• Consult with us about the inner diameter, film thickness, and shrinkage rate, as the dimensions that can be casted will vary depending on the balance of the three.

• TST can provide shrinkage force such that heating at 150 to 200˚C results in 8 to 15% of shrinkage.

• The inner surface can be etched to support adhesive processing.

• It is also possible to add coloring and conductivity.

Scroll to see more

GF TUBE®

GF Tube is a trademark or registered trademark of Gunze Limited.

GF Tube is a trademark or registered trademark of Gunze Limited.

- NST/SMT

Gunze’s thinnest heat-shrinkable/non-shrinkable tube, made even thinner by using fluororesin PFA.

In addition to pure products, various types are available, including those with conductivity, improved heat dissipation, and improved internal surface wetting.

• Possible film thickness dimensions depend on the balance between length and inside diameter.

Please contact our sales office.

GF Tube is a trademark or registered trademark of Gunze Limited.

GF Tube is a trademark or registered trademark of Gunze Limited.

Product videos

Features

Conductive

Weather resistant

Slippery

Water repellent, non-adhesive

Chemical resistant

Uses

Fusing rolls and transfer rolls for office equipment

Bag applications

Fluorescent tube scattering prevention

Mold stain prevention

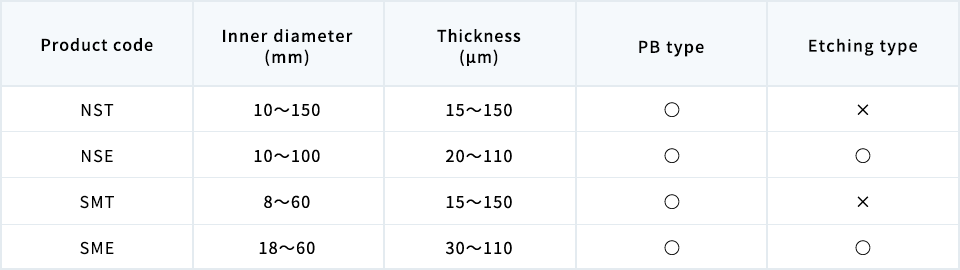

Standard specifications

Since this product is made-to-order, please contact our sales office.

We will provide the best solution to meet your request.

Scroll to see more

• Consult with us about the inner diameter, film thickness, and shrinkage rate, as the dimensions that can be casted will vary depending on the balance of the three.

• SMT shrinks 8 to 12% by heating at 180 to 290˚C. Consult us about processing.

• Consult us about internal surface treatment.