- HOME

- SiC/SiC Composites

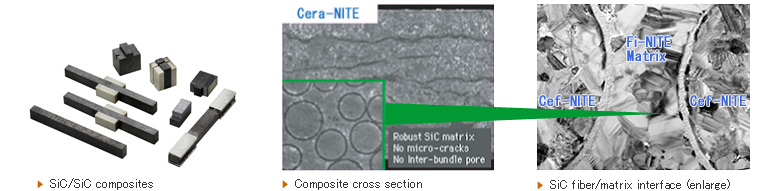

The SiC/SiC composite “Cera-NITETM” is an SiC/SiC composite with high hardness and high fracture resistance, realized by connecting the SiC fiber “Cef-NITETM” and the SiC nanopowder “Fi-NITETM” at the nano-level boundary, based on the NITE※ method as an SiC/SiC composite production method.

※ The NITE method, an abbreviation of “Nano-powder Infiltration and Transient Eutectic Process”, is a production method for SiC/SiC composites with high durability and high heat resistance, developed by Professor KOYAMA, at that time at Kyoto University. IEST has obtained from JST the exclusive rights for the patent regarding the NITE method.

(Photos: Provided by IEST)

| Reinforcing material | SiC fibers:“Cef-NITETM” |

|---|---|

| Fiber volume fraction | Approximately 45 % (flexible control is possible according to the design) |

| Fiber interface | Pyrolytic carbon |

| Reinforcement fiber architecture | Unidirectional (UD), cross ply (± 90℃), plain weave, satin weave, etc. |

| Matrix raw material | (β-SiC) SiC nanopowder |

| Shape | Plates, tubes, blocks, etc. (external dimensions up to 500 mm) |

| Main applications |

|