- HOME

- SiC Fiber

- As a structural stiffener for metal, resin, and ceramic composite materials

-

- ・For consumer use (cylinders, heat exchangers, engine parts, chemical plants, etc.)

- ・For existing energy systems (fuel rods for nuclear power generation etc.)

- ・For next-generation nuclear reactors (fuel rods, intermediate heat exchangers, etc.)

- ・Fusion reactors (blankets etc.)

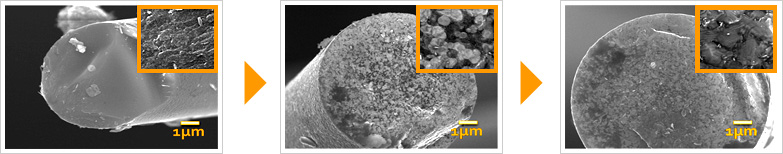

Crystallization process for SiC fibers

(Photos: Provided by IEST)

The microstructure of “Cef-NITETM” SiC fibers is composed of SiC with high crystalline and chemical stoichiometric composition. It maintains excellent properties at extremely high temperatures up to 1,800 degrees, and the SiC/SiC composite “Cera-NITETM” produced according to the NITE※ method has high reliability as a structural material for extremely high temperatures. The SiC fiber “Cef-NITETM” is an innovative fiber material indispensable for the production of the SiC/SiC composite “Cera-NITETM”.

※ The NITE method, an abbreviation of “Nano-powder Infiltration and Transient Eutectic Process”, is a production method for SiC/SiC composites with high durability and high heat resistance, developed by Professor KOYAMA, at that time at Kyoto University. IEST has obtained from JST the exclusive rights for the patent regarding the NITE method.

“F-NITETM”, “Cef-NITETM”, and “Cera-NITETM” are registered trademarks of IEST.