Product InformationAD

- Nylon6 100%

AD

- #For Industrial material

Mono-filament transparent thread

Attraction of AD

- 1.Fit any colors

-

Offer a transparant sewing thread by making full use of mono-filament's characteristics. Even materials of different colors, it will match naturally without thinking about color matching.

- 2.Why use mono-filament?

-

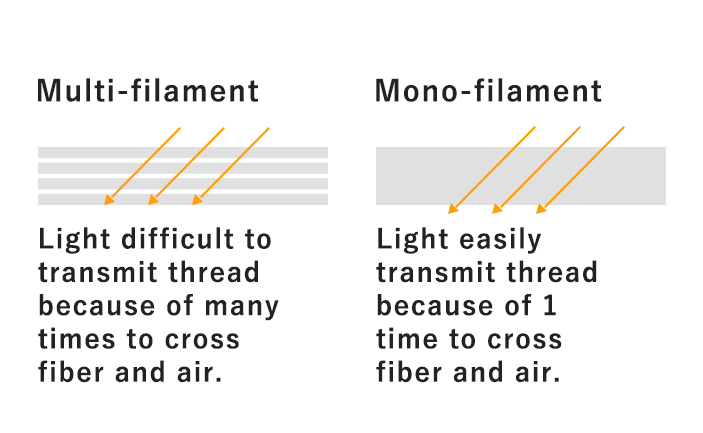

Usually sewing threads are made by twisting a number of fine fibers; filament, to give them strength and flexibility; multi-filament.

However, even if each fiber is transparant, if multiple fibers are overlapped, the transparancy will drop and the thread will not be transparant to match any color. Since AD is composed of one; mono, fiber, its sewing thread is more transparant than ordinary sewing threads.

- 3.Not suitable for clothes but...

-

Since AD is mono-filament, it might irritate the skin and is not suitable for clothing. However, furniture that does not come into direct contact with the skin such as sofa, chair, curtain, sandals, slippers and etc... is the best for AD and it can use with confidence for these products.

-

- Abundant count development.

- Easily color matching of transparent thread.

- (This thread might irritate the skin because of mono-filament.)

- (Yellowing might be caused because the main textile is nylon.)

Standard Physical Properties

| Article Number |

TEX/ Tkt |

Length (m) |

Component | Size (dtex) |

Average Strength (cN) |

Extension (%) |

Number of Color |

Color Card |

|---|---|---|---|---|---|---|---|---|

| 20 | 70/40 | 2,000 | 700dtex×1 | 710 | 2,800 | 55±15 | Transparent | - |

| 30 | 50/60 | 2,000 | 470dtex×1 | 465 | 1,870 | 60±15 | Transparent | - |

| 40 | 40/75 | 2,000 | 370dtex×1 | 365 | 1,430 | 60±15 | Transparent | - |

| 50 | 24/120 | 5,000 | 235dtex×1 | 230 | 910 | 60±15 | Transparent | - |

| 60 | 18/180 | 5,000 | 167dtex×1 | 165 | 640 | 60±15 | Transparent | - |

| 80 | 14/220 | 5,000 | 135dtex×1 | 135 | 520 | 60±15 | Transparent | - |

- *1 TEX and Tkt are reference value.

- *2 The size is managed within a range of ±5%.

Main Uses

|