The Konan Plant’s ZEB office building

Producing comfortable and pleasant spaces

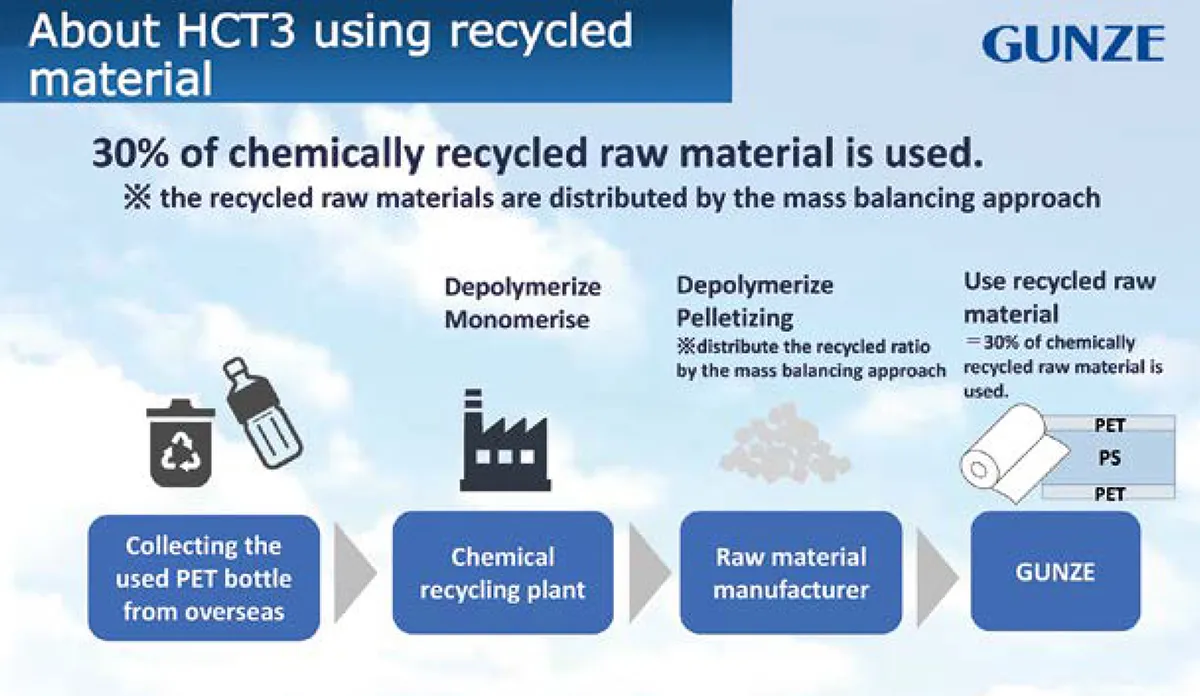

The Gunze Group has taken steps to convert its Moriyama Factory, a key plant in the plastic films field, into a resource-recycling plant (a plant that recycles

resources without producing waste). In the future, we will transition from a manufacturer that sells plastic films to a recycling-based circular manufacturer.

In April 2023, work on the Circular FactoryTM was completed at our Moriyama Plant after around four years of planning with the aim of utilizing solar and

groundwater energy, achieving zero emissions and the elimination of plastic waste, and producing sustainable products. From the completion ceremony until the end of

May 2024, we received just under 1,200 visitors from approximately 200 companies (organizations). Due to the COVID-19 pandemic, sales representatives visited

customers infrequently. As a result, there were fewer opportunities to obtain feedback regarding issues and needs. Visits to the Circular FactoryTM have contributed

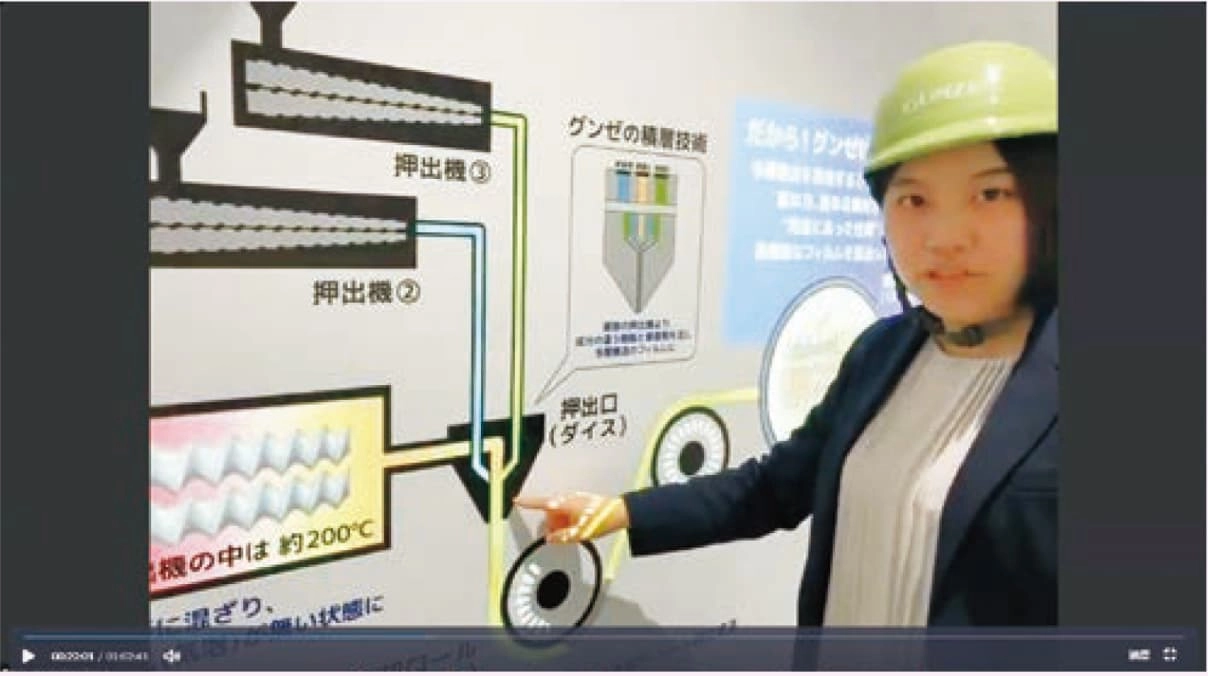

to concrete proposals for environmental responses, which in turn have led to a variety of collaborative projects. We are also holding online factory tours for

overseas customers, and our real-time responses are being well received.

In the Moriyama Plant’s management office, there is a whiteboard that displays information for plant visitors and monthly tour schedules that are filled with almost

no blanks and updated daily. The visitors are mostly business clients, but there are also many government and local government officials. Previously, due to

concerns about maintaining confidentiality, we rarely had the opportunity to show people from outside the Company around the factory. The reason why the new plant

even has walkways to welcome visitors is because resource recycling initiatives are difficult for a single company to achieve alone. For example, recycling requires

cooperation from local governments and stakeholders, while the development of materials requires cooperation from customers with expertise in recycling technology

and waste disposal. In terms of promoting resource circulation, it is necessary to involve the entire industry. For this reason, we have boldly shifted to a

strategy of disclosing new initiatives.

The reactions from visitors have been positive, and we are beginning to see model cases of resource circulation. However, this activity will probably not

immediately lead to an increase in sales. We will continue our activities in the belief that these initiatives serve as stepping stones for future strategies.

Online briefing for overseas customers