Product Development Innovation

Gunze’s core technologies lie in the development of different types of laminated films.

In particular, the hybrid shrinkable film made by laminating polystyrene (PS) and polyester (PET) has two properties—high shrinkability (attractiveness) and

rigidity (film thinning)—and is therefore being widely used not only for PET bottles, but also for irregularly shaped containers and toiletry products that have

poor heat resistance.

Gunze has leveraged its strengths in the selection and processing of a wide variety of raw materials to develop distinctive films and create value.

However, recycling is made more difficult when a film made up of multiple different materials is separated into its individual components, so the trend toward

mono-material films, which are made up of a single material to facilitate recycling, is becoming mainstream worldwide.

On the premise of utilizing its multilayer-oriented film technology to that end, Gunze would like to resolve the recycling issue by establishing film separation

and recycling technologies.

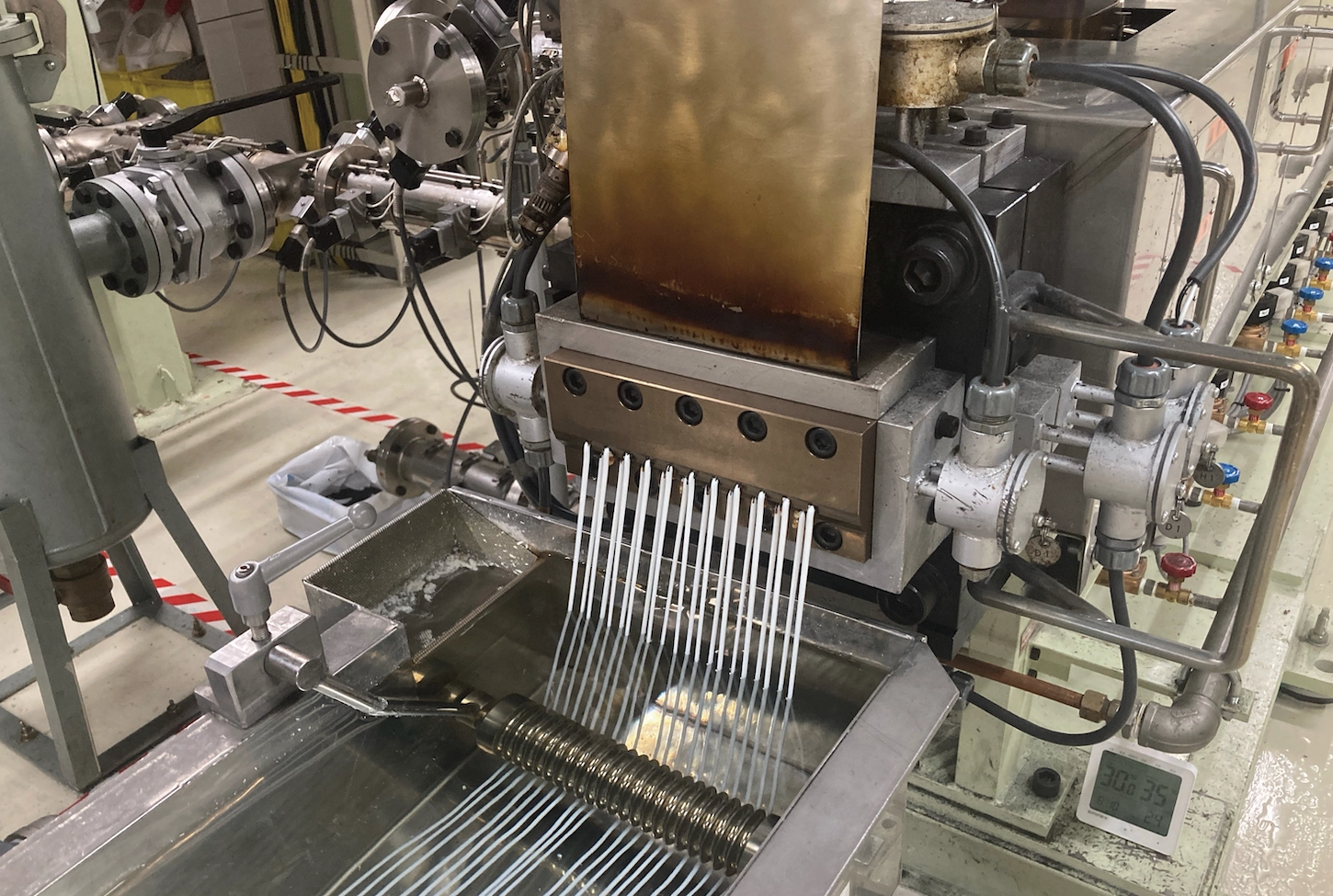

The experimental equipment for separating different types of materials was completed in February 2024.

In addition to recycling within the Company, in the years to come we will incorporate manufacturing waste generated by customers into our films to increase the

recycled content rate of our products.

We have already launched products containing recycled materials onto the market.

At the end of FY2022, we launched GEOPLAS® HCT3, for which 30% recycled materials are used, and at the end of FY2023 we launched GEOPLAS® HCX1, the lightest in

the industry with 5% recycled material content.

Although the latter has a lower recycling rate, it is the lightest product in the industry thanks to the use of thin-film technology to reduce the amount of

material used.

We will also increase the recycled content rate and work to supply products made from 100% recycled materials by 2030.

I would like us to use the Moriyama Factory as a model Circular Factory™ and apply our know-how to other production sites, thereby transforming ourselves into a

circular manufacturer.

The experimental equipment for separating different types of laminated films

Beverage bottle labels for which GEOPLAS® HCX1 was adopted

Circular Factory™ Visitor Hosting Activities (Plastic Films Business)

In April 2023, work on the Circular FactoryTM was completed at our Moriyama Plant after around four years of planning with the aim of utilizing solar and

groundwater energy, achieving zero emissions and the elimination of plastic waste, and producing sustainable products. From the completion ceremony until the

end of May 2024, we received just under 1,200 visitors from approximately 200 companies (organizations). Due to the COVID-19 pandemic, sales representatives

visited customers infrequently. As a result, there were fewer opportunities to obtain feedback regarding issues and needs. Visits to the Circular FactoryTM have

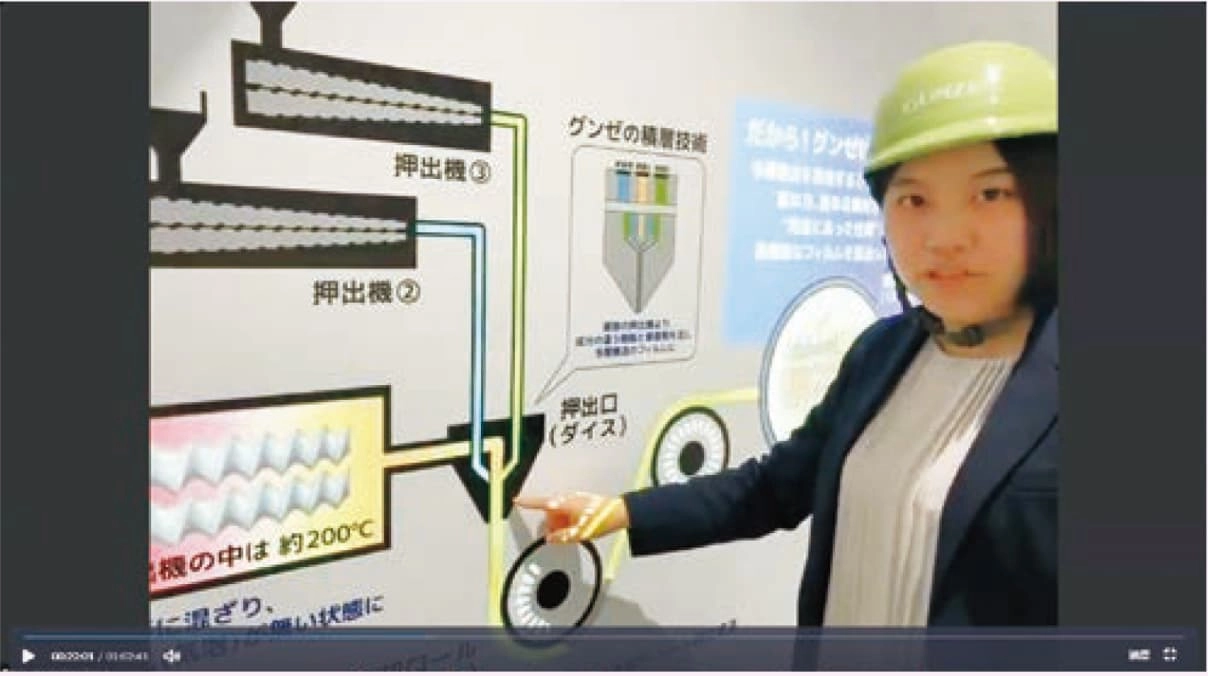

contributed to concrete proposals for environmental responses, which in turn have led to a variety of collaborative projects. We are also holding online factory

tours for overseas customers, and our real-time responses are being well received.

In the Moriyama Plant’s management office, there is a whiteboard that displays information for plant visitors and monthly tour schedules that are filled with

almost no blanks and updated daily. The visitors are mostly business clients, but there are also many government and local government officials. Previously, due

to concerns about maintaining confidentiality, we rarely had the opportunity to show people from outside the Company around the factory. The reason why the new

plant even has walkways to welcome visitors is because resource recycling initiatives are difficult for a single company to achieve alone. For example,

recycling requires cooperation from local governments and stakeholders, while the development of materials requires cooperation from customers with expertise in

recycling technology and waste disposal. In terms of promoting resource circulation, it is necessary to involve the entire industry. For this reason, we have

boldly shifted to a strategy of disclosing new initiatives.

The reactions from visitors have been positive, and we are beginning to see model cases of resource circulation. However, this activity will probably not

immediately lead to an increase in sales. We will continue our activities in the belief that these initiatives serve as stepping stones for future strategies.

Online briefing for overseas customers

External view of the Circular Factory™