Technology Strategy

Pursue Technology-Driven Solutions to Meet Customer Needs and Drive Global Growth Strategy

Manufactured Capital Cultivated Since Our Founding Gunze has a history that spans 130 years.

Strengths and Challenges in Manufactured Capital Building on the technological assets it has cultivated over many years, Gunze has extended the technologies it developed in the apparel business into growth fields, such as medical products and engineering plastics.

Initiatives under VISION 2030 stage2

Under the Medium-term Management Plan VISION 2030 stage2 (FY2025-FY2027), we will strengthen manufactured capital to enhance quality and reduce costs by increasing

productivity, while also establishing a sustainable production system.

Our specific initiatives are:

1. Establish smart factories through automation and digital technologies

We will utilize image processing, sensing, handling and other automation technologies, and digital technologies, including AI, to visualize and optimize production

processes and the entire supply chain.

By reducing reliance on manual processes, we will address challenges, such as the transfer of skills and the labor shortage, to improve productivity and quality.

2. Establishing production processes that minimize environmental impact

We will introduce renewable energy and resource-circulating practices at all plants, both in Japan and overseas, aiming to reduce the environmental burden of

production while also generating profit.

A good example is the Circular FactoryTM at our Moriyama Plant within our Plastic Film Company.

It is a model for environmentally responsible production.

Through these efforts, Gunze will reinforce its manufactured capital, the bedrock of manufacturing, to build a sustainable and competitive corporate structure for

the future, while contributing to solutions to social issues and continuing to deliver better products and services to customers.

Continued Innovation in Manufacturing Technologies

Since VISION 2030 stage1, Gunze has been an innovator in the field of manufacturing technologies, with a focus on automation and digital solutions.

In stage2, we will continue to advance and strengthen these technologies, rolling them out throughout the Company.

In automation, we have combined elemental technologies, such as image processing, sensing, and handling technologies, to automate processes that previously depended

heavily on people.

In stage1, we successfully built an automated bonding-sewing line for apparel products by integrating handling technologies to pick up delicate fabric sheets one at

a time, sensing technologies to transport and place them precisely, and image-processing technologies to apply adhesives accurately.

In stage2, we will extend these technologies to the highly complex sewing processes in the apparel business and the manufacturing of bioabsorbable medical products

in the medical business.

Full-scale operations are scheduled to begin in the second half of FY2025.

We will also promote the automation of inspection processes, which still rely significantly on skilled human visual inspection procedures, across all of our

business units.

With the future labor shortage in mind, we are working to enhance accuracy, improve speed, and reduce workload using image processing and automated conveyance

technologies.

Strengthening the Digital Strategy

In parallel, we are strengthening our digital strategy.

In stage1, we introduced digital tools in our sales and back-office functions to redesign workflows.

This included the visualization of management data using a management dashboard, streamlining routine tasks with Robotic Process Automation (RPA), and managing and

visualizing KPIs to reduce inventory.

These efforts have advanced efficiency and transformed the organization.

In stage2, we will use AI to further strengthen our digital strategy.

Companywide, we will introduce ChatGPT-based tools to share knowledge and support businesses while also building a knowledge system for maintenance operations using

Retrieval-Augmented Generation (RAG) technology.

In production and supply chain management (SCM), we will use AI to optimize scheduling and monitor inventory data in real time, preventing stockouts and

overstocking, and thereby reducing storage costs.

By continuing to innovate in the field of manufacturing technologies, we aim to realize sustainable and competitive manufacturing while delivering new value to

society and our customers.

Automated bonding-sewing line for apparel products

Automated bonding-sewing line for apparel products

The Sustainable Strengthening of Intellectual Capital Through the Creation and Development of Differentiated Technologies and Intellectual Property

Our Fundamental Technologies and Intellectual Capital

The Gunze Group’s fundamental technologies, are fiber processing technology, resin processing technology, and the integration of manufacturing technology with

equipment development, and they are recognized as components of its intellectual capital.

These accumulated strengths form the foundation of the Group’s business.

Our business divisions proactively develop products and technologies based on the needs of customers while continuing to strengthen and develop existing

technologies.

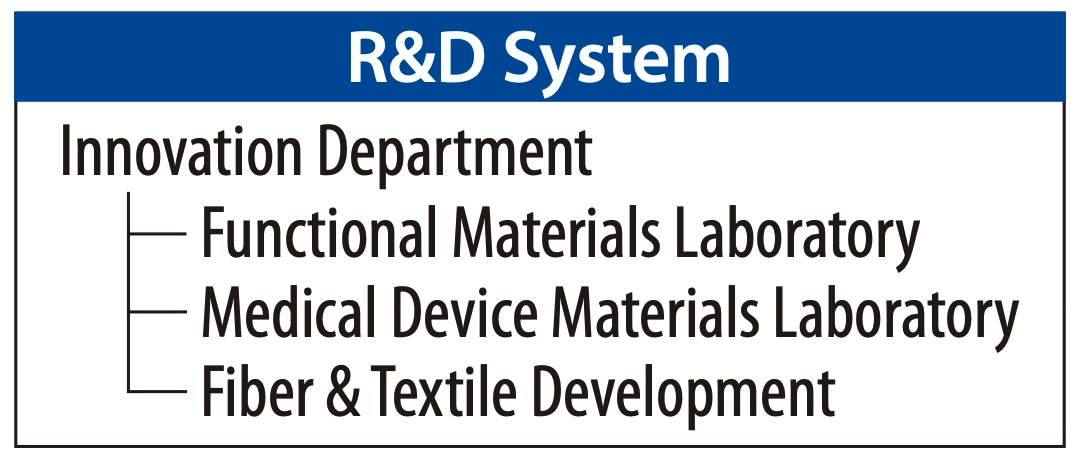

At the same time, the Technology & Development Department and the Innovation Department, which are both head office functions, lead cross-organizational,

medium- to long-term initiatives to reinforce and develop fundamental technologies.

The Technology & Development Department focuses on reforming cost structures by creating smarter processes, while the Innovation Department is dedicated to

creating new and differentiated technologies.

By managing and leveraging the results of these technological efforts as intellectual property, we ensure that we are able to sustainably increase our

intellectual capital.

Gunze Group R&D expenditures

Gunze’s fundamental technologies

R&D Structure and Focus Areas

In April 2025, Gunze reorganized its R&D structure into three laboratories aligned with its key business domains, functional solutions, medical, and apparel, to

strengthen the foundation of each business.

Each laboratory focuses on the research and development of raw materials and processing technologies in its own field, working to develop differentiated technologies

that are the basis for new high-value-added product lines.

The Functional Materials Laboratory carries out R&D regarding the design and molding of composite and multilayer materials made using high-performance resins, building

on and further advancing our accumulated technologies.

The Medical Device Materials Laboratory conducts R&D on bioabsorbable materials and processing technologies with the goal of creating distinctive high-value-added

products that address real-world medical needs.

The Fiber & Textile Development continues to develop the modification and fabric processing technologies we have accumulated in pursuit of products that deliver comfort

solutions for life.

Leveraging the material design and raw material processing expertise cultivated in the Functional Solutions business, the laboratory also develops high-performance

fibers not only for apparel applications but also for industrial use.

These R&D activities are supported by our expanded collaboration with companies outside the Group and academic institutions, along with reinforced cross-functional

cooperation within the Group.

All of these efforts are aimed at achieving more effective and efficient results.

Intellectual Property Development

To solidify the accumulated technologies that we regard as our intellectual capital, it is essential that we document tacit knowledge, such as the expertise

and ideas of individuals, and manage it systematically as IP rights and expertise.

We believe that continuously rebuilding our IP portfolio while ensuring it stays aligned with our corporate and business strategies is essential to the

achievement of sustainable growth and development.

To this end, we have established the IP Division as a head office function.

It is responsible for formulating and promoting IP initiatives in line with our corporate strategy.

In particular, we emphasize the establishment of a robust IP portfolio to reinforce the foundation of our business.

This involves analyzing our proprietary IP assets in priority business domains, together with trends in the market and our competition, and sharing these

findings with each business division.

By integrating this information with various other data, we identify the technology areas to be reinforced and establish policies for each domain.

Building on this foundation, we are advancing initiatives through cross-divisional collaboration.

To bridge the IP initiatives with the R&D and business divisions, we appoint heads of development in each division as division patent officers (DPOs).

These DPOs closely collaborate with the IP Division to strengthen alignment with business strategies and accelerate the making of decisions and management

related to intellectual property, including the development of IP and responses to violations of IP rights.

Expansion of Intellectual Property

To encourage the creation of IP, we present the Da Vinci Award, an original corporate accolade, to the inventors of patents and innovations that significantly

contribute to our business.

The award ceremony is held in a dialogue format, with the President personally listening to the inventors’ ideas and development stories.

It is positioned as an annual tradition that conveys our respect and appreciation for our engineers.

In recent years, the business divisions and the IP Division have strengthened their collaborations in the area of resource circulation technologies, plastic

recycling in particular, to further expand our IP portfolio.

This growing body of IP is the vital foundation that enables the Gunze Group to actively contribute to a sustainable society, and its value will only continue to

increase going forward.

| FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|

| Patents held | Domestic | 655 | 691 | 680 |

| Overseas | 249 | 249 | 228 | |

| Designs | Domestic | 200 | 216 | 248 |

| Overseas | 8 | 10 | 10 | |

| Trademarks held | Domestic | 1,946 | 1,934 | 1,914 |

| Overseas | 796 | 803 | 802 | |

Recipient of the FY2025 Intellectual Property Achievement Award

In FY2025, the Gunze Group received the Japan Patent Office Commissioner’s Award during the Intellectual Property Achievement Awards in recognition of its initiatives

to effectively utilize the intellectual property rights system.

Key points of the evaluation of Gunze included:

(1) The appointment of division patent officers (DPOs) to serve as central drivers of IP activities in each business division

(2) The prioritization of plastics recycling technology and the proactive promotion of the creation of IP in this field

(3) The effective use of an IP mix (patents, designs and trademarks) throughout business operations