Recycled coat hangers made from plastic waste

About GUNZE

Business

Research & Development

Sustainability

Investor Relations

Osaka-Gunze Limited (Headquarters: Osaka, Japan, President: Toshiyasu Saguchi) [TOKYO: 3002] is pleased to announce that Gunze will introduce recycled coat hangers that recycle film waste from plastic film production for its seasonal men's innerwear "Hot Magic" in the fall and winter of 2022.

Gunze began its plastics business by developing a packaging film for its own pantyhose products and is now developing shrinkable labels for beverages, food, toiletries and other products as well as films for vegetables and other fresh foods.

As a social responsibility of the company that manufactures and sells plastic film packaging materials, Gunze established a “Basic Policy towards a Recycling System for Plastics” in December 2019 and is working to establish a system for recycling plastic as a resource. The film used in the Recycle Hanger is the only environmentally friendly olefin* shrink film that Gunze has developed for labels, and products using this film were introduced to the market this summer. The Recycle Hanger is a zero-waste initiative unique to Gunze, which has both plastics and apparel businesses. By expanding sales of olefin film, which can effectively utilize petroleum, a depletable resource, and is easy to recycle, Gunze plans to re-label products that have been sold as labels in the future.

*Olefin is a general term for polymer compounds such as polyethylene and polypropylene.

Recycled coat hangers made from plastic waste

The recycled hangers are made from discarded plastics. These include plastic film waste from the manufacturing process and discarded beverage bottle caps.

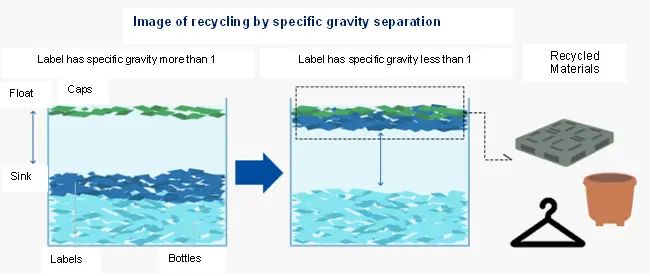

Among the plastics produced from petrochemicals, those with a specific gravity of less than 1 are olefin materials. Olefins are the most widely used raw materials for general-purpose resins. Because olefins have a specific gravity of less than 1, they produce the greatest amount of plastic from the same volume of petroleum, making it possible to make effective use of the limited resource of petroleum.

PET beverage bottles consist of several raw materials, including the bottle, cap and label. In Japan, sorting has been advanced for some time, but in other countries, low recycling rates have been a problem that has not been solved due to cost and efficiency. By expanding the use of olefin labels, which are easy to recycle due to their specific gravity separation, the company aims to achieve "label-to-label" recycling, where used labels are reused as labels, in the same way that used PET bottles are reused as raw materials for PET bottles in "bottle-to-bottle" recycling of PET beverage bottles.

Gunze, founded in Kyoto in 1896, is a leading developer and manufacturer of plastic films, engineering plastics, medical devices and apparel. Gunze employs more than 5,200 people in 10 countries worldwide.

Established in 1962, the Plastic Films business has a significant presence in 20 countries. It has three manufacturing plants in Japan and subsidiaries in the United States, Vietnam and China. Gunze's mission will continue to focus on improving the quality of life by providing innovative products and solutions.

*Plastic Film business website:https://www.gunze.co.jp/plastic/e/